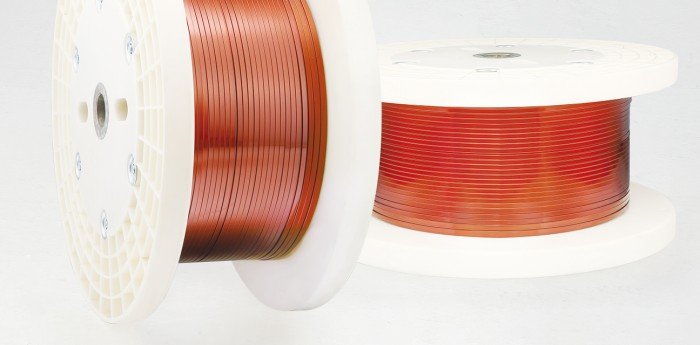

Enameled rectangular wire is a metal conductor insulated with varnish, most of the time, the enameled rectangular copper wire is wound into coils of different shapes to generate magnetic force, used in motors, transformers, magnets, etc.

Conductor material of enameled wire

Copper is the standard conductor material for enameled wire, with excellent electrical conductivity and very good windability. For lighter weight, larger diameter enameled wire, aluminum can sometimes be used as the conductor material for enameled wire. Since aluminum wire is difficult to contact with oxidation issues, copper-clad aluminum can help to make a compromise between copper and aluminum. For special applications, we offer a variety of conductor materials for enameled wire, such as brass, silver, nickel, gold, stainless steel, or copper alloys with special characteristics such as higher mechanical strength or bending properties. In addition, the core conductor can be plated with different materials, such as silver or nickel.

Outer diameter of enameled wire

International standards group magnet wires according to specific outer diameter ranges. IEC standards classify magnet wire insulation as Class 1, 2, or 3, NEMA as single, multi-layer, or triple-layer, and JIS as Class 0, Class 1, Class 2, or Class 3. The tolerances in these magnet wire standards can be further restricted if the winding coil and final product need to be designed and optimized.