Photovoltaic modules are the smallest components with packaging and internal connections.Photovoltaic cellsModule equipment can provide direct current alone and cannot be divided. It is the core component of the photovoltaic power generation system and is composed of eight core materials. So today, let us walk into the ambitious photovoltaic industry and learn about the scientific and technological knowledge of the eight main materials of the module!

Photovoltaic module materials

1. Battery Cell

The cell is the core component of the module. It is mainly used to convert light energy into electrical energy. After the cells are connected in series and parallel, a certain rated output power and voltage are achieved to form a photovoltaic module. Photovoltaic modules are combined into a photovoltaic array. Connected with controllers, battery packs, inverters and other components, a photovoltaic power generation system is formed.

Solar CellsAccording to the raw materials, they are divided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. At the same time, the crystalline silicon cell technology uses silicon wafers as the substrate and PN junction as the basis for photogenerated carrier separation and power generation. According to the raw materials and battery preparation technology, crystalline silicon cells are divided into P-type cells and N-type cells. P-type silicon wafers are made by doping boron into silicon materials. P-type battery preparation technologies include traditional AL-BSF (aluminum back surface field) and PERC technology. N-type silicon wafers are made by doping phosphorus into silicon materials. In other words, there are many N-type battery preparation technologies, including PERC, TOPCon, IBC and HJT.

2. Tempered glass

Photovoltaic glass is a kind of soda-lime silicate glass, which is mainly used for the encapsulation of photovoltaic modules. Photovoltaic glass will directly affect the power generation efficiency and service life of photovoltaic modules.

Photovoltaic glass is generally low-iron tempered glass or semi-tempered glass, which has the following characteristics:

First, good light transmittance. Light transmittance is a key factor affecting the conversion efficiency of photovoltaic cells. At the same time, photovoltaic glass needs to have high light transmittance and high reflectivity of 1200nm infrared light.

Second, high mechanical strength. It has strong impact resistance and can withstand 2400Pa wind pressure and 5400Pa snow pressure. At the same time, it plays a supporting and protective role.

Third, good durability. Affected by the climate and geographical location, the components need to work in the open air and in an environment with a large temperature difference between day and night, and they need to be resistant to corrosion and weathering.

3. Adhesive film

Photovoltaic encapsulation film is an important component of photovoltaic modules and is located on the upper and lower surfaces of the battery. The main function of the film is to bond the battery to the glass and backplane. Secondly, the film can play a protective role, protecting the battery circuit from interference from the external environment and extending the service life of the module. In addition, the encapsulation film can increase the light transmittance of the photovoltaic module, thereby improving the power generation efficiency of the module. Finally, during the production, storage, installation and use of the module, the film can also serve as a structural support to position the battery.

According to the different materials, the mainstream films are EVA, POE, EPE and PVB. EVA film is the mainstream photovoltaic encapsulation film, which has the characteristics of good light transmittance, good processing performance, stable supply and low cost. POE film has low water vapor permeability and good PID resistance, and is suitable for double-glass modules and N-type modules, but has poor processing performance and high cost.

4. Back panel

Photovoltaic backsheet is a packaging material used for back protection, generally used for single-glass modules. Photovoltaic backsheets are divided into fluorine-containing backsheets and fluorine-free backsheets. Of course, fluorine-containing backsheets include TPT, TPE, TPC, CPC, and fluorine-free backsheets include PET, PA/PO, etc.

Photovoltaic backsheets are mainly used to resist the erosion of materials such as cells and films by humidity and heat, and play the role of anti-corrosion, anti-weathering, anti-oxidation, and insulation protection. At the same time, they can effectively extend the service life of the components. In addition, the white backsheet has a high reflectivity, which can improve the conversion efficiency of the components. At the same time, high infrared reflectivity is also conducive to reducing the operating temperature of the components.

5. Frame Kit

Photovoltaic frame is a frame installed on the outer extension of glass. It is mainly used to fix and seal solar panels. It is conducive to the transportation and installation of photovoltaic panels. The installation of the frame is conducive to protecting the edge of the glass and strengthening the sealing performance of photovoltaic panels. At the same time, the frame is a link carrier that carries the components and the bracket. In addition, the use of the frame can improve the overall mechanical strength and load resistance of the component, thereby extending the service life of the component.

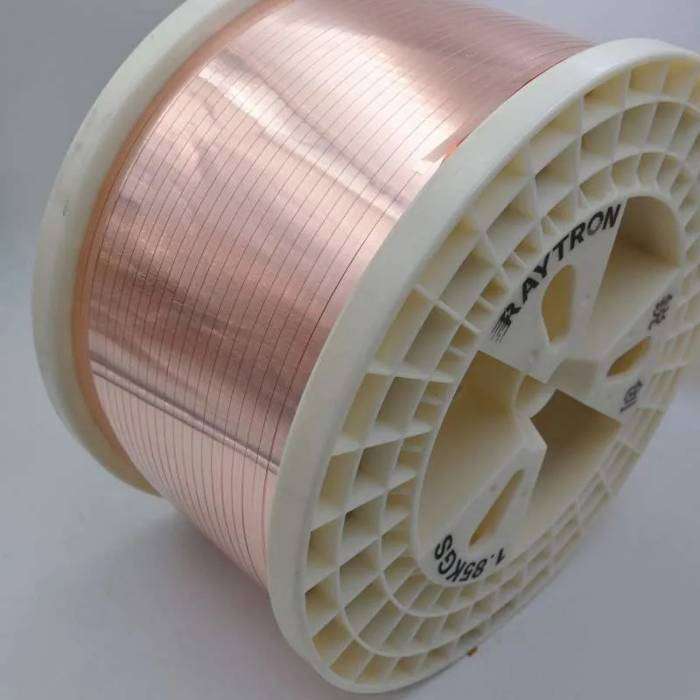

6. Photovoltaic welding ribbon

Photovoltaic welding ribbon is also calledTinned copper strip, mainly divided into photovoltaic pull-ring wire andPhotovoltaic busbarThe photovoltaic ribbon is mainly used to connect the photovoltaic module cells. The photovoltaic busbar is mainly used to connect the module cell strings. At the same time, it will collect the current generated by the solar cell into the junction box.RaytronNew Energy (Zhejiang) Co., Ltd. provides photovoltaic welding ribbons.

7. Silicone

Silicone is mainly used for bonding and sealing laminated glass photovoltaic modules, bonding frames and glass, junction boxes, back panels (or glass), and plays a role in sealing and connecting.

According to the different places of use, silicone is divided into sealants and potting compounds. Sealant is used in the frame slot, junction box and the bottom of the backplane. Potting compounds are generally used inside the junction box, and their main function is to protect the internal circuit of the junction box.

8. Junction Box

The main function of the junction box is to connect the electricity generated by the solar cell to the external circuit. Normally, it can play a role in sealing, waterproofing and dustproofing, connecting the wires of the photovoltaic module. At the same time, the junction box also has the function of protecting the safe operation of the photovoltaic module system. In addition, if a short circuit occurs in the module, the junction box will automatically disconnect the short-circuited battery pack to prevent the entire system from being burned.