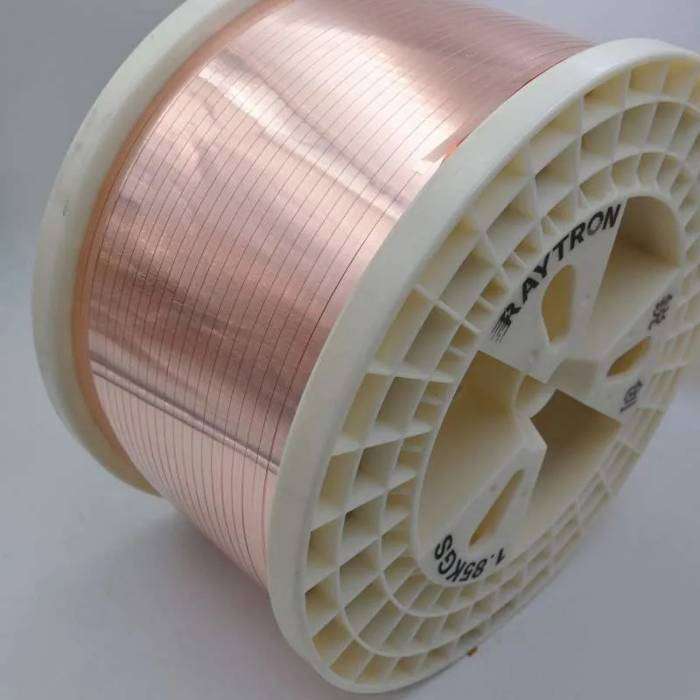

Photovoltaic welding ribbonAs importantPhotovoltaic modulesOne of them is directly related to the performance and stability of photovoltaic cell modules.RaytronPhotovoltaic welding ribbon stands out in the industry for its excellent quality and becomes the first choice trusted by the industry.

High purity material, excellent conductivity

Ruichuang photovoltaic welding ribbon uses high-purity oxygen-free copper as the main raw material, ensuring excellent electrical conductivity. Its excellent conductivity not only reduces the energy loss during current transmission, but also provides more stable power output for photovoltaic cell modules.

Exquisite craftsmanship ensures reliable quality

During the manufacturing process, Ruichuang pays attention to the exquisite craftsmanship of every link, adopts advanced production equipment and strict quality control process. This not only guarantees the mechanical properties and corrosion resistance of the welding strip, but also gives it excellent fatigue resistance, ensuring that it can maintain stability under long-term high-intensity use.

Advanced technology, innovation-driven development

Ruichuang is committed to the innovation and upgrading of photovoltaic ribbon technology, and continuously introduces advanced production technology and processes. Its R&D team not only has rich experience, but also maintains close cooperation with leading institutions in the industry to ensure that the product reaches the international leading level in performance and reliability.

Diversified products to meet different needs

Photovoltaic welding tapes have various application scenarios. In order to better meet the needs of different customers, Ruichuang provides welding tape products of various specifications and models. From thin wires to flat wires, from different thicknesses to different widths, users can choose the most suitable products according to actual needs to achieve personalized customization.

The photovoltaic welding ribbons produced by Ruichuang are of first-class quality and play a vital role in applications. However, even the best products have their shelf life. In order to ensure the performance and life of the products, correct storage methods are essential.

Here are some suggestions:Help you extend the service life of photovoltaic ribbon:

Keep dry: PV ribbons are extremely sensitive to moisture and are easily oxidized by moisture. When storing, choose a place with low relative humidity. If possible, use a dehumidifier in the storage area.

Avoid exposure to air: Once opened, the PV ribbon will quickly react with oxygen in the air. Therefore, try to avoid exposing the ribbon to the air for too long, especially in a high temperature and high humidity environment.

Take protective measures: Before use, you can consider applying some protective coating on the surface of the solder strip to slow down its oxidation reaction with air. This method can effectively reduce the oxidation rate and extend the service life.

Vacuum packaging: Choose vacuum packaging with moisture-proof properties to reduce the contact of the solder strip with moisture. This helps keep the solder strip dry and reduces the risk of oxidation.

Regular inspection: It is recommended to inspect the opened solder strips regularly. If any signs are found that the solder strips may have been oxidized or otherwise damaged, timely measures should be taken to prevent further deterioration.

The correct storage method not only helps to extend the life of the photovoltaic welding ribbon, but also ensures that it can perform at its best when used. It is a good habit to use it as soon as possible after purchase, which is not only beneficial to product quality, but also helps to improve work efficiency.

As a leader in the photovoltaic welding ribbon industry, Ruichuang looks forward to working with you all the way in the future!