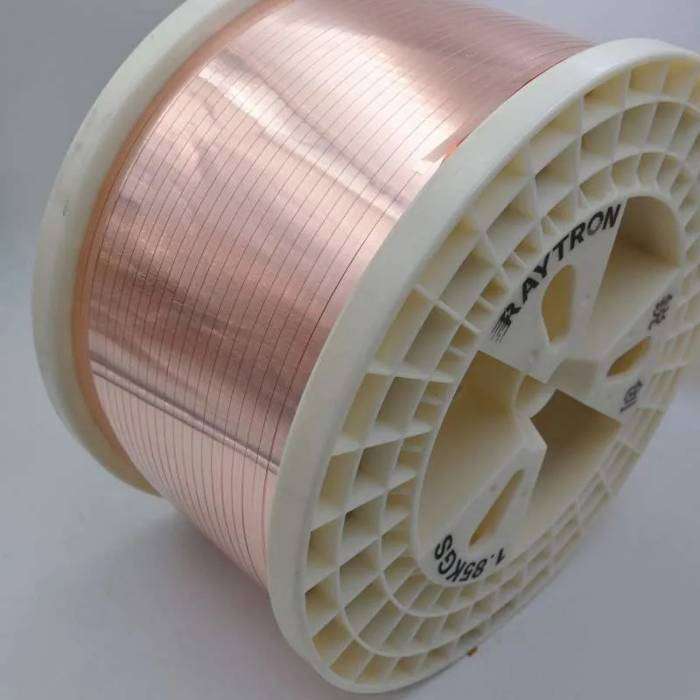

Copper clad aluminum stripThe electrical conductivity of Copper Clad Aluminum (CCA) is one of its core properties and also determines whether it can be used inPhotovoltaic welding ribbonThe key factor to replace pure copper materials in the fields of power, cable, etc.Conductive properties of copper clad aluminum stripDetailed description:

? Overview of the Conductive Properties of Copper Clad Aluminum Strip

Copper clad aluminum strip is composed of high purity aluminum core and outer layer of pure copper.High conductivityWith aluminumLightweight properties, its overall conductivity is better than pure aluminum and close to the level of copper.

?? Conductive performance parameters

| index | Numerical Description |

|---|---|

| Conductivity | Generally 60%~65% IACS(Depending on the thickness of the copper layer) |

| Resistivity | about 0.028~0.030 Ω·mm2/m |

| Surface conductivity | Close to pure copper, good for welding and conduction |

| Current carrying capacity | Compared with pure copper of the same cross section, 80%, by increasing the cross-sectional area (e.g. 1.5 times) the equivalent current carrying capacity can be achieved |

| High frequency performance (skin effect) | The copper layer conducts mainly.Outperforms pure aluminum in high-frequency applications |

? Several key advantages of copper-clad aluminum conductivity

- Conductive effect close to that of pure copper: Because the current is concentrated on the surface of the conductor (skin effect), the copper layer can carry the main current.

- Lightweight and low resistance: Copper-clad aluminum can provide a larger volume than copper at the same weight, thereby reducing the overall resistance per unit length.

- Good welding performance: The surface layer is copper, which is suitable for conventional photovoltaic welding processes and does not require special adjustments.

- Customizable copper layer thickness:likeRaytronCompanies such as AT&T can provide copper layer thickness ≥0.05mm to meet higher conductivity requirements.

?? Actual engineering data example

- One 0.2×5mm copper clad aluminum welding strip, copper layer thickness 0.05mm, overall conductivity can reach ≥62% IACS.

- If you want to replace 100% copper material, you only need to enlarge the cross-sectional area to About 1.5 times, you can achieveSame current carrying capacity and voltage drop performance.

? Precautions when using

- A copper layer that is too thin will affect conductivity, so the uniformity of the copper layer must be strictly controlled during production.

- Using inferior CCA products (such as loose copper layer bonding, thin copper layer) will lead to problems such as increased resistance and heat accumulation.It is particularly important to choose high-quality manufacturers such as Ruichuang.