The production process of resistor copper strips usually involves multiple steps, and each link needs to be strictly controlled to ensure the quality and performance of the final product. The following is the production process of resistor copper strips:

1. Raw material preparation

Copper material selection: Choose high-purity copper material (usually 99.9% purity or above) to ensure good conductivity and ductility.

Cleaning: Clean the surface of the raw materials to remove the oxide layer and impurities to ensure smooth subsequent processing.

2. Cutting

Cutting into sections: Cutting large pieces of copper into small sections of appropriate lengths to prepare for subsequent rolling and drawing.

3. Smelting

Smelting treatment: Smelting copper materials at high temperatures to remove impurities and form a uniform copper liquid to ensure the consistency of the material.

4. Casting

Casting: The molten copper is cast into copper wire, which is then cooled to form the initial shape of the copper material.

5. Hot rolling

Hot rolling: The copper wire is initially rolled through a hot rolling mill to reduce its thickness and improve its internal structure.

6. Cold rolling

Cold rolling: The hot-rolled copper wire is cold rolled to further reduce the thickness and width to the required specifications.

7. Pulling

Drawing into wire: Through the drawing process, the copper strip is drawn into a resistor copper strip, and its diameter, shape and strength are controlled.

8. Annealing

Annealing: Annealing is performed on the drawn copper wire to eliminate internal stress and improve flexibility and ductility. Protective atmosphere annealing is usually used to prevent oxidation.

9. Surface treatment

Surface finishing: Polishing, cleaning and other treatments are performed on the copper wire to ensure surface smoothness and prevent oxidation and corrosion.

10. Quality Inspection

Inspection process: Conduct comprehensive quality inspection on finished products, including diameter, tensile strength, conductivity, surface quality, etc., to ensure that the products meet the standards.

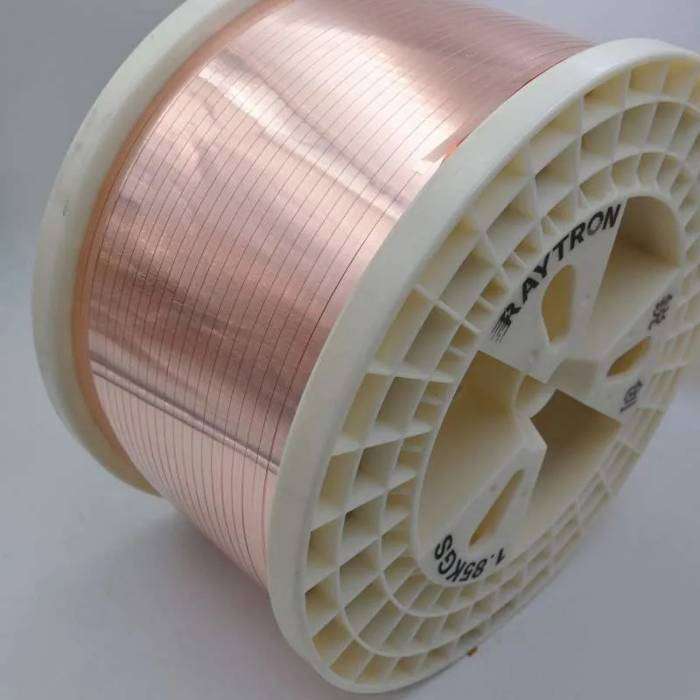

11. Cutting and packaging

Cutting finished products: Cut qualified copper wire into lengths specified by customers.

Protective packaging: Packed with anti-oxidation materials to ensure that it is not damaged during transportation and storage.

12. Storage and delivery

Storage management: Place finished products in a suitable environment until they are shipped or picked up by customers.

Summarize

The production of resistor copper strip is a complex process involving multiple links such as raw material selection, smelting, casting, rolling, drawing, annealing, surface treatment, etc. Each step needs to be strictly controlled to ensure that the final product has excellent conductivity and mechanical strength.