1. Photovoltaic modules: The foundation of solar power generation

Solar CellsComponents = Solar Panels:

Since the output voltage of a single solar cell is low, and the electrodes of unpackaged cells are easily detached due to environmental influences, a certain number of single cells must be packaged in series and parallel.

Photovoltaic modules are located between photovoltaic cells and photovoltaic systems and are the final products of the photovoltaic manufacturing industry.

2. The preparation of photovoltaic modules includes two main steps: cell interconnection and lamination.

① Cell interconnection: The standard number of cells in a photovoltaic module is 60 or 72, corresponding to 10 or 12 copper wires asPhotovoltaic busbarThe six groups are connected to form one photovoltaic module.

②Lamination: After the cells are interconnected, they are generally packaged together in the order of tempered glass, film, cell, and backplane. The backplane and tempered glass encapsulate the cells and film inside, and are protected by aluminum edges and silicone sealing edges. After the lamination process, the service life of photovoltaic modules can be significantly improved, and the environmental resistance and mechanical properties can be significantly optimized.

3. Currently, there are two technical directions for photovoltaic cells, namely bifacial components and half-chip packaging.

Bifacial modules: Photovoltaic modules that use bifacial cells. They are characterized by the ability to generate electricity on both the front and back sides. When sunlight shines, part of the light is reflected by the surrounding environment to the back side of the module. Bifacial modules have the ability to collect this part of the light energy, thereby increasing the amount of electricity generated.

Obviously, bifacial cells can generate more electricity than traditional single-sided designs. This can effectively reduce the average cost of power generation. Correspondingly, the production process of bifacial cells is also more complicated. The opaque traditional backsheet cannot be used on the back, and the superimposed other production processes lead to slightly higher costs.

② Half-cell packaging: The current mainstream packaging mode. It refers to cutting the battery into two halves of equal size in a direction perpendicular to the main grid line of the battery. The current generated by photovoltaic cells during power generation is related to the battery area. When the half-cells are connected in series, the resistance of a single positive and negative circuit remains unchanged. The power loss of a single circuit is reduced to 1/4 of the original, thereby reducing the overall power loss of the component. At the same time, it also reduces the negative impact of component heating on power generation.

4. Several factors affecting the power output of photovoltaic modules

① Hotspot effect

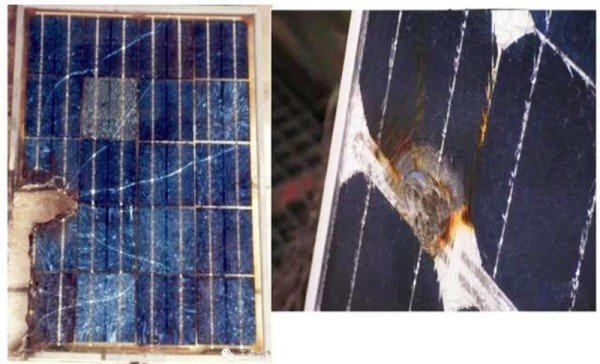

The partially shaded solar cell modules will act as loads, consuming the light energy generated by other solar cell modules. The shaded solar cell modules will become hot at this time, which is the hot spot effect.

This effect can seriously damage solar cells. Some of the energy generated by an illuminated solar cell can be consumed by cells in the shadow. The cause of the hot spot effect can be as simple as a piece of bird droppings.

In order to prevent solar cells from being damaged by the hot spot effect, it is best to connect a bypass diode in parallel between the positive and negative electrodes of the solar cell module to prevent the energy generated by the illuminated module from being consumed by the module in the shadow. When the hot spot effect is severe, the bypass diode may be broken down and the module may be burned.

②PID effect

Hidden cracks are a defect in cells. Due to the characteristics of the crystal structure, crystalline silicon cells are very easy to break. The production process of crystalline silicon modules is very long, and many links may cause hidden cracks in the cells. In recent years, in order to reduce costs, crystalline silicon module manufacturers have been moving towards thinner and thinner crystalline silicon cells. This reduces the ability of the cell to prevent mechanical damage.