Photovoltaic welding ribbonIntroduction

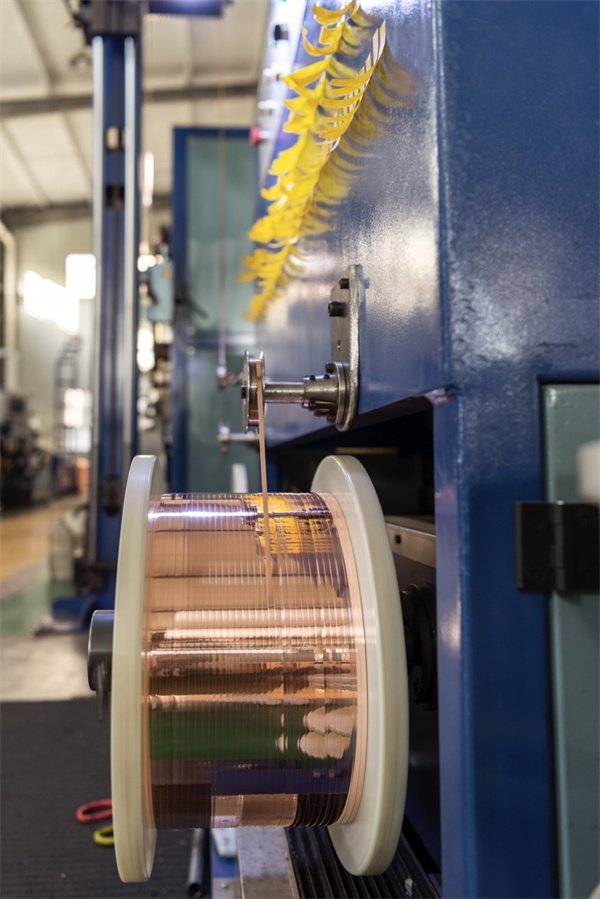

Photovoltaic ribbon, also known asTinned copper strip/Tap Strips/Interconnect Strips.RaytronThe conventional dimensions of photovoltaic ribbons are: 1-6mm wide, 0.08-0.5mm thick, with a 10-30um thick flux coating. We usually use it forPhotovoltaic modulesConnections between batteries.

The photovoltaic cells connected by the photovoltaic ribbon are encapsulated by EVA film, photovoltaic glass, back sheet, frame and other materials to form photovoltaic modules. Then we can apply it to the construction of photovoltaic power generation system. The quality of the film production line is related to the transmission efficiency and service life of photovoltaic modules. The performance indicators of photovoltaic ribbons such as size, mechanical properties, surface structure, resistivity, etc. are important factors affecting photovoltaic power generation efficiency, the breakage rate of photovoltaic cells, and the long-term reliability and durability of photovoltaic modules.

The effect of photovoltaic welding ribbon on components

Photovoltaic welding ribbon is an important raw material in the welding process of photovoltaic modules. The quality of photovoltaic welding ribbon will directly affect the current collection efficiency of photovoltaic modules. It also has a great impact on the power of photovoltaic modules.

In the process of connecting the cells in series, we must firmly weld the photovoltaic ribbon to avoid the phenomenon of cold welding. Therefore, when selecting the photovoltaic ribbon, the manufacturer must determine the state of the photovoltaic ribbon according to the characteristics of the selected battery.

Manual welding requires the soldering tape to be as soft as possible. Soft soldering tape will be very good on the soldering iron and will come into contact with the battery. The stress generated during the welding process is very small, which can reduce the breakage rate. However, a soldering tape that is too soft will reduce the tensile strength and is easy to break. For the automatic welding process, the soldering tape can be slightly harder. This is conducive to the welding machine to straighten and press weld the soldering tape. A soldering tape that is too soft is easy to deform when welded by a machine, thereby reducing the product yield.

Photovoltaic ribbon isSolar CellsThe photovoltaic ribbon is a key component in the solar panel. It is an important factor in improving the efficiency and durability of the solar panel. The high efficiency and durability of the solar panel can only be achieved by using high-quality photovoltaic ribbons that are correctly installed in the solar panel. Therefore, the quality of the photovoltaic ribbon and its welding with the solar cell is an important factor in ensuring the efficiency and durability of the solar panel.

Selection of photovoltaic ribbon

The thickness of the photovoltaic ribbon is determined by the thickness of the battery and the size of the short-circuit current. The width of the photovoltaic ribbon should be the same as the width of the battery's main grid line. The softness and hardness of the photovoltaic ribbon generally depend on the thickness of the battery and the welding tools.

Generally, we divide photovoltaic welding ribbons into interconnecting strips (connected to the battery. We weld it on the grid line with the battery). And busbars (connected to the battery string and junction box), according to different uses.

The main raw materials of photovoltaic ribbons are copper and tin. The base material and the surface coating constitute them. The base material is copper of different sizes, which requires precise specifications, good conductivity, and a certain strength. The surface coating is a tin alloy. It can be coated with tin alloy and other coating materials according to a certain composition ratio. And special processes such as electroplating, vacuum deposition, spraying or hot dipping are used to evenly coat the surface of the copper substrate with a certain thickness. Since the copper substrate itself does not have good welding properties. The main function of the tin alloy layer is to make the tabulation line meet the weldability and firmly weld the photovoltaic ribbon to the main grid of the battery, so as to play a good current conduction role.

Interconnect and Bus Bars

Normally, we connect the cells in series with interconnecting ribbons and weld them to the main grid of the cell. It has the function of collecting and transmitting the current of the photovoltaic cells.

The busbar is a strip that connects the photovoltaic cell string and the junction box, and does not directly contact the cell. Its function is to transmit the current of the photovoltaic cell string.

In a typical silicon solar cell, both are required. And the interconnect bar is what we actually solder to the silicon crystal, connecting the solar cells in the solar panel to each other. And the interconnect bar carries the current generated by the solar cell to the photovoltaic bus. This is a hot-dip tinned copper conductor that is installed around the perimeter of the solar panel. It connects the interconnect bars together.