1. Product Overview

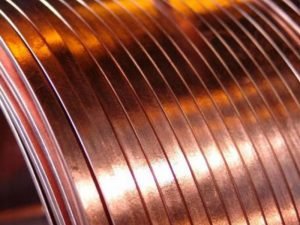

Copper-aluminum composite materials are used. The main material specifications include copper-aluminum ratios of 40/60, 50/50, and 60/40, as well as other customized specifications. The product thickness is 0.05-1mm and the width is 1-10 mm, combining light weight and high conductivity.

2. Material specifications

Main copper-aluminum ratio: 40/60, 50/50, 60/40

Thickness tolerance: ±0.003 mm

Width tolerance: ±0.015 mm

Structural form: cold rolled composite, support R angle customization

3. Performance indicators

Electrical conductivity: ≥65 %IACS

Tensile strength: ≥120 MPa

Elongation: ≥10 %

Surface roughness: Ra ≤0.4 μm

Oxidation stability: ≥ 100 h at 100 °C without discoloration

4. Typical Applications

PCB shielding interconnect

Lightweight energy busbar

High frequency signal cable

Flexible electronic and medical component connectors

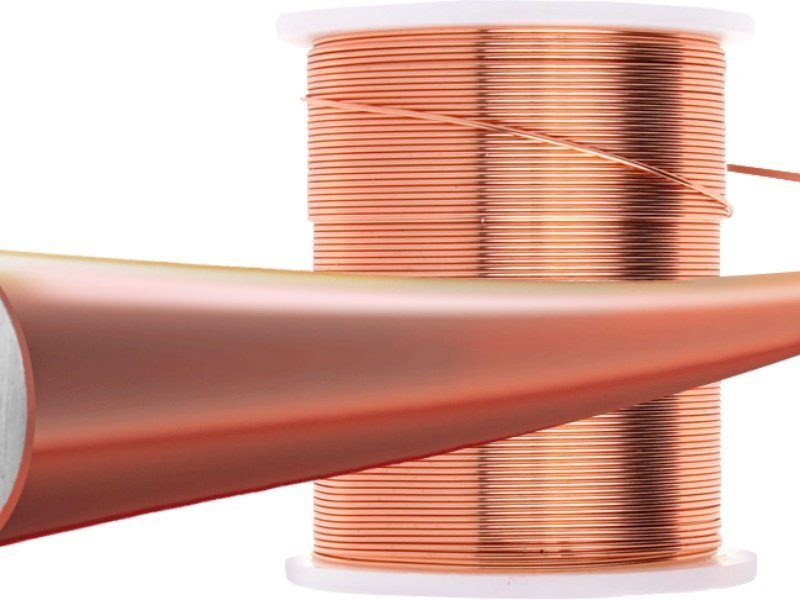

5. Packaging information

Plastic or steel shaft packaging, 10KG-200KG/roll, with anti-oxidation packaging, suitable for feeding automatic welding equipment.

Raytron can produce product size specifications | |||||||||||||||||||

| Width (mm) | |||||||||||||||||||

| Thickness (mm) | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.2 | 2.4 | 2.6 | 2.8 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| 1 | √ | √ | √ | √ | |||||||||||||||

| 0.95 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 0.9 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 0.85 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 0.8 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 0.75 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| 0.7 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||

| 0.65 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 0.6 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 0.55 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 0.5 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.4 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.35 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.3 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.25 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 0.18 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 0.16 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.12 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.1 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.09 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.08 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 0.07 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||

| 0.06 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 0.05 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 0.04 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 0.035 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 0.03 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||